Beirut Blast:

The tragic Beirut Blast has drawn varying reactions from anguish to anger or despair to dismay. And naturally our hearts go out to the residents and victims of the City of Beirut whose lives have been devastated with this incident.

As reports emerged that Ammonium Nitrate was the Chemical tragically involved in the explosion and following devastation to the port and city of Beirut, previous world events involving this product immediately flash in our minds. From Tianjin, China to Texas, USA or from Ryongchon, North Korea to Oppau, Germany, memories stream through and quite instinctively I can see Ports and Ship Owners in their boardroom huddles asking each other the pointed questions on what should be our approach on Ammonium Nitrate handling and storage going forward.

One would expect, quite instinctively, the reactions to incidents of such magnitude has to express grave concern with this product at the bare minimum for those who do not have intimate knowledge of Ammonium Nitrate and its properties. Suffice to say the Explosives Grade Ammonium Nitrate industry is highly regulated in most countries as well as globally through the UN Recommendation on the Transport of Dangerous Goods – Manual of Test and Criteria, Model Regulations Volume 1 and 2, International Maritime Dangerous Goods Regulations, IMO Recommendations on the Safe Transport of Dangerous Goods and Related Activities in Port Areas etc. etc.

In my opinion, it is not the lack of adequate regulatory control (plenty of which is in place) but the lack of the application of knowledge and experience that leads to incidents such as this. The key here is “application” – knowledge and experience exceeding perhaps a 100 years is out there but it just needs to be sought out to avert such disasters.

When in doubt, I would urge you to reach out to the experts in your network before you take action or make a decision on a new path forward with Ammonium Nitrate. Alternatively, you can contact myself and I will be either happy to assist or put you in touch with a relevant expert in that area. We need to collectively support the industry with our collective knowledge and experience over a hundred years as millions of tons of Ammonium Nitrate will continue to be moved from Plant to Pit to keep mining ticking along!

Brian Devaraj

BEIRUT BLAST PROMPTS AMMONIUM NITRATE DEBATE

Source:- TheDCN 7th August, 2020

AN EXPLOSION at Beirut port, blamed upon the dangerous storage of ammonium nitrate, has prompted discussion about how this chemical is being both stored and handled in Australia.

The blast killed in the order of 100 people and devastated the port and surrounding areas.

Shipping company CMA CGM Group, which has a large presence in Beirut, has issued a further statement confirming the death of one of their staff members.

“We are deeply affected by this tragedy and extend our condolences to his family, colleagues and all of his loved ones,” the company said in a statement.

There are four ammonium nitrate manufacturing plants in Australia; Kwinana Western Australia (CSBP Wesfarmers), Newcastle NSW (Orica), Gladstone Queensland (Orica) and Moura Queensland (Queensland Nitrates).

Ammonium nitrate is used in mining.

The proximity of some of these locations to human populations has prompted some to question whether they are appropriate for storage.

The Orica storage facility near Newcastle, adjacent to Newcastle Port, is one that has generated discussion.

Newcastle’s stockpile of between 6,000 to 12,000 tonnes is stored at Orica’s Kooragang Island plant in the Port of Newcastle, according to the company.

“It’s a totally inappropriate place to have such a dangerous material produced and stored, and it’s something we’ve been complaining about for many, many years,” said chemical engineer and community campaigner Keith Craig.

In a statement to the ABC, Orica said thousands of tonnes of ammonium nitrate is stored at the site on any given day, but “stringent practices” were in place.

“Ammonium nitrate storage areas are fire resistant and built exclusively from non-flammable materials,” the statement said.

“There are no flammable sources within designated exclusion zones around these areas.”

The company told the ABC operations on Kooragang Island were highly regulated under numerous state and federal standards, and the facility holds a Major Hazard Facility licence.

Port of Newcastle head of corporate communications Sam Collyer said ammonium nitrate was never stored at the port.

“The product is removed from the berth by truck immediately after its arrival,” Mr Collyer said.

Melbourne University chemicals expert Dr Gabriel Silva, who has been to Kooragang Island several times, said ammonium nitrate posed little risk with appropriate storage.

“The real message is, if you handle this material as you should, and as we know to so safely, then the risk is minimised,” Dr Silva told DCN.

Meanwhile the Maritime Union has issued a statement linking the Beirut blast with the use of foreign-flagged ships.

According to the MUA, the union had “repeatedly warned” the Australian government that the reliance on poorly-regulated foreign flag-of-convenience vessels — like the “unseaworthy” Russian-owned, Moldovan-flagged Rhosus which delivered the explosive material to Beirut —posed “a significant safety risk”.

“The situation in Beirut, where a dangerous cargo arrived on an unseaworthy flag-of-convenience vessel that lacked the ability to safely store it, could easily be repeated in Australia,” MUA national secretary Paddy Crumlin said.

“Dangerous goods like weapons-grade ammonium nitrate come in and out of Australian ports on flag-of-convenience ships without any process to ensure they can safely carry that dangerous cargo, or that their crew members don’t pose security risks.”

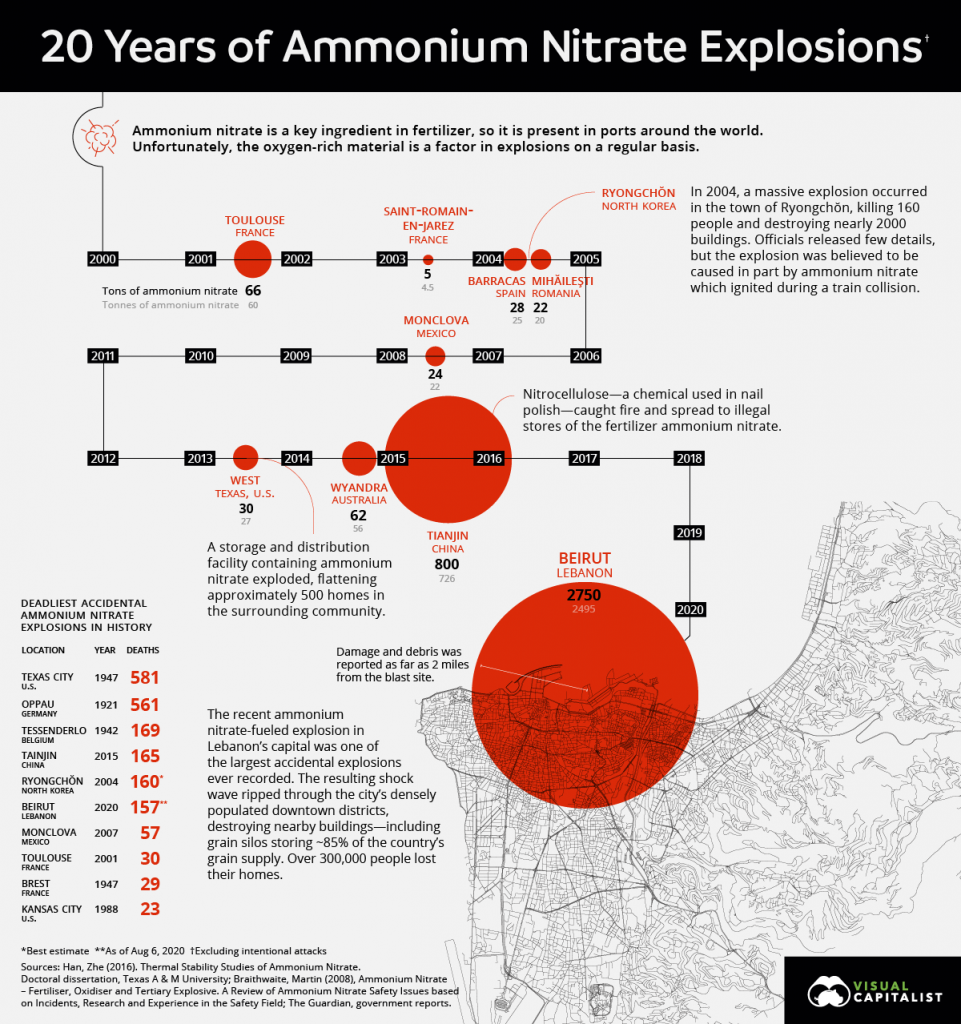

The Biggest Ammonium Nitrate Explosions Since 2000

Source:- VisualCapitalist

The Biggest Ammonium Nitrate Explosions Since 2000

This week, a massive explosion involving ammonium nitrate rocked the city of Beirut, sending shock waves through the media.

This recent tragedy is devastating, and unfortunately, it’s not the first time this dangerous chemical compound has caused widespread damage.

Today’s graphic outlines the biggest accidental ammonium nitrate explosions over the last 20 years.

A Brief Explanation of Ammonium Nitrate

Before getting into the details, first thing’s first—what is ammonium nitrate?

Ammonium nitrate is formed when ammonia gas is combined with liquid nitric acid. The chemical compound is widely used in agriculture as a fertilizer, but it’s also used in mining explosives. It’s highly combustible when combined with oils and other fuels, but not flammable on its own unless exposed to extremely high temperatures.

It’s actually relatively tough for a fire to cause an ammonium nitrate explosion—but that hasn’t stopped it from happening numerous times in the last few decades.

The Death Toll

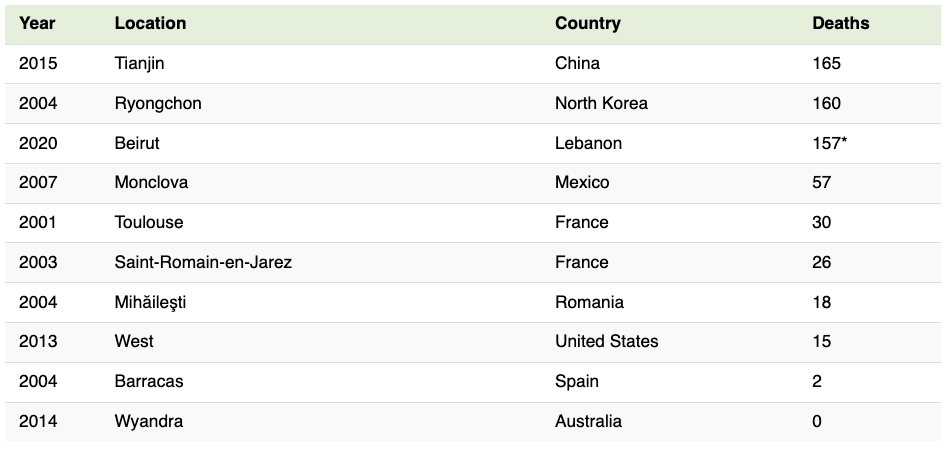

Some explosions involving ammonium nitrate have been deadlier than others. Here’s a breakdown of the death toll from each blast:

One of the deadliest explosions happened in Tianjin, China in 2015. A factory was storing flammable chemicals with ammonium nitrate, and because they weren’t being stored properly, one of the chemicals got too dry and caught fire. The blast killed 165 people and caused $1.1 billion dollars in damage.

In 2001, 14 years before the explosion in Tianjin, a factory exploded in Toulouse, France. The accident killed 30 people and injured 2,500. The power of the blast was equivalent to 20 to 40 tons of TNT, meaning that 40 to 80 tons of ammonium nitrate would have ignited.

In addition to factory explosions, there have been several transportation accidents involving ammonium nitrate. In 2007, a truck in Mexico blew up and killed over 57 people. Filled with explosives, the truck crashed into a pickup, caught fire, and detonated. The blast left a 60-foot long crater in its wake.

The Aftermath

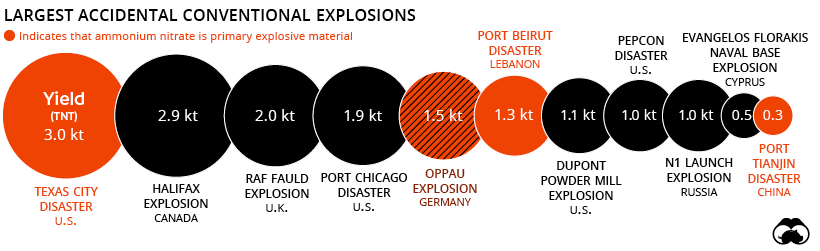

While there have been several ammonium nitrate accidents throughout history, the recent tragedy in Beirut is one of the largest accidental explosions ever recorded, with 157 deaths and 5,000 injuries and counting.

In terms of TNT equivalent, a measure used to gauge the impact of an explosion, it ranks in the top 10 of the largest accidental explosions in history:

Topping the list is yet another ammonium nitrate explosion, this time back in 1947.

Known to history as the Texas City Disaster, the port accident was one of the biggest non-nuclear explosions to occur in history. The explosion killed over 500 people and injured thousands. The impact from the blast was so intense, it created a 15-foot wave that crashed along the docks and caused flooding in the area.

A Resource With Trade-Offs

Despite being dangerous, ammonium nitrate is still a valuable resource. There’s been an increased demand for the chemical from North America’s agricultural sector, and because of this, ammonium nitrate’s market size is expected to see an increase of more than 3% by 2026.

Because of its increasing market size, it’s more important than ever for trade industries to enforce proper safety measures when storing and transporting ammonium nitrate. When safety regulations aren’t followed, accidents can happen—and as we saw this week, the aftermath can be devastating.

Ports around the world review ammonia nitrate storage plans in wake of Beirut blast

Source:- splash247 11th August 2020

Ports around the world are actively reviewing their ammonia nitrate storage guidelines in the wake of last Tuesday’s terrible explosions that decimated much of the Lebanese capital, Beirut.

Ammonium nitrate is formed when ammonia gas is combined with liquid nitric acid. The chemical compound is widely used in agriculture as a fertiliser, but it’s also used in mining explosives. Around 2,750 tons of it was stored for seven years near fireworks in a warehouse in the port of Beirut before going up in a gigantic fireball seven days ago leading to the deaths of more than 160 people with many more still unaccounted for.

On the ground at the disaster zone chemical experts and firefighters are working to secure at least 20 potentially dangerous chemical containers at the port, after finding one that was leaking.

Lebanese security officials warned the prime minister and president as recently as last month that the ammonium nitrate stored in the port posed a security risk and could destroy the capital if it exploded. Earlier warnings from port officials had also been ignored by the authorities.

Lebanon’s president has asked investigation authorities to look into any signs of “external interference” that may have caused the blast.

“The cause has not been determined yet. There is a possibility of external interference through a rocket or bomb or other act,” President Michel Aoun said.

Aoun, who had previously said explosive material was stored unsafely for years at the port, said the investigation would also weigh if the blast was due to negligence or an accident. Twenty people had been detained so far.

Online publication Visual Capitalist has provided a chart carrying details of the biggest ammonium nitrate explosions over the past 20 years, with Beirut’s blast dwarfing every other one combined so far this century.

Sri Lanka Ports Authority assures safe handling of dangerous cargo under UN regulations

Source:- PortNews 20th August 2020

The Sri Lanka Ports Authority (SLPA) assured the business community and the general public that all Lankan seaports were safe from dangerous cargo as they were handled in conformity with UN regulations.

This assurance came from Sri Lanka Ports Authority Chairman General Daya Ratnayake in the aftermath of the explosion at the Beirut seaport in Lebanon last week, where 2750 tonnes of Ammonium Nitrate, imported and stored from 2014, exploded. The SLPA Chairman was responding to a question from Local Media as to whether similar threats existed in the Sri Lankan seaports as well.

This also follows President Gotabaya Rajapaksa telephoning the SLPA Chairman last Wednesday during which the President had told him to take fresh stock of the situation and to rectify any shortcomings if there were any. This was followed by a meeting on Friday morning which was chaired by the SLPA Chairman which had SLPA officials, Customs officials the four Terminal Operators, Jaye Container Terminal (JCT), South Asia Gateway Terminals (SAGT) which operates Queen Elizabeth Quay and Colombo International Container Terminals which operates the Colombo Terminal of the Colombo South Port.

The SLPA Chairman told local media that there were the Ports of Colombo, Galle, Trincomalee and Hambantota which came under the SLPA. He said that there were various cargoes which included explosives, dangerous chemicals which were handled by the ports, but which were handled and discharged under the guidelines of the International Maritime Organization (IMO), the security arm of the United Nations. These guidelines have been specified by the International Maritime Dangerous Goods Code and the nine categories under that are: Explosive materials (Class 1), Gases (Class 2), Flammable Liquids (Class 3), Flammable Solids (Class 4), Oxidizing Substances and Organic Pesticides (Class 5), Toxic and Infectious Substances (Class 6), Radioactive Materials (Class 7), Corrosive Materials (Class 8) and Miscellaneous Dangerous Substances ( Class 9)

Meanwhile, SLPA Additional Managing Director, Upali de Zoysa, told the local media, that all the port operators have taken the maximum precautious regarding the handling of dangerous cargo while taking the minimum risk in accordance with the UN regulations.

He said that a majority of the cases where explosives were imported were the three Armed Forces which were also discharged expeditiously. If certain items which were not collected by the consignee, they would be auctioned by the Port Operators within 21 days, he said.

Further to my last post on the Beirut Blast on 4th August 2020, I read with interest the attached article on the situation with the safe handling of dangerous goods at Sri Lankan Ports. While it is heartening to note that the SLPA has sprung into action to review the risk profile of its ports with respect to handling of all Classes of Dangerous Goods including Class 5.1 Ammonium Nitrate, it concerns me that the reference point is the IMDG which I would respectfully point out that this IMO (IMDG)Code is specifically focussed on Carriage of Dangerous Goods on board ships and does not pertain to storage and handling of Dangerous Goods in Port Areas. While there may be some common principles that can be drawn, the conditions and risk profile of a dangerous cargo on board a ship is quite different to that in a Port Area. At best the IMO Publication: Revised Recommendations on the Safe Transport of Dangerous Cargoes and Related Activities IN Port Areas 2007 Revised Edition should be a good point of reference when it comes to assessing the risk profile of a port with respect to dangerous goods. This publication is somewhat limited on Class specific guidance – it covers Class 1 Explosives and Class 7 Radioactives in some detail albeit limited but does not cover other Classes including Class 5.1 Ammonium Nitrate. This is where ports handling such dangerous cargoes need to engage with industry experts on logistics of such dangerous cargoes to ensure the risks associated with handling and storage are identified and adequate controls are in place to ensure the Port is operating, at bare minimum, at ALARP (as low as reasonably practicable) risk levels. It would be recommended that a detailed Class specific (product specific if warranted) SOP be drafted and posted on the Port Website for easy access for all port users. A quick check on some Port websites indicate this is not the case which perhaps needs to be addressed with urgency to ensure lessons learnt from past incidents are not ignored.